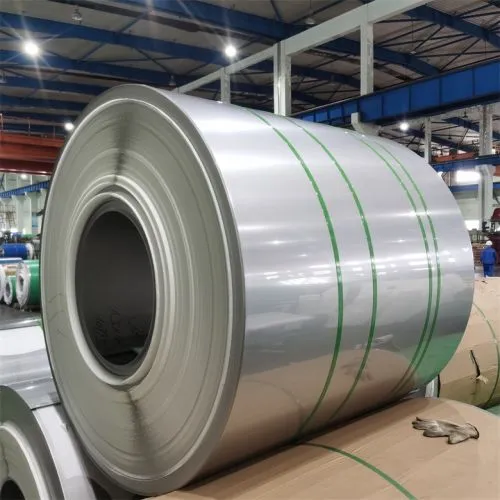

UNS S32654 - EN 1.4652

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quote

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A QuoteUNS S32654 is a super austenitic stainless steel with excellent properties and wide applications.

Chemical Composition

| Element | Composition (%) |

| Carbon (C) | ≤ 0.020 |

| Silicon (Si) | ≤ 0.50 |

| Manganese (Mn) | 2.00 - 4.00 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.005 |

| Chromium (Cr) | 24.0 - 25.0 |

| Nickel (Ni) | 21.0 - 23.0 |

| Molybdenum (Mo) | 7.00 - 8.00 |

| Copper (Cu) | 0.30 - 0.60 |

| Nitrogen (N) | 0.45 - 0.55 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

| Tensile Strength, Ultimate (UTS) | 850 MPa |

| Tensile Strength, Yield (Proof) | 490 MPa |

| Elongation at Break | 45% |

| Reduction in Area | 46% |

| Shear Strength | 590 MPa |

| Fatigue Strength | 450 MPa |

| Poisson's Ratio | 0.28 |

| Brinell Hardness | 220 |

| Elastic (Young's, Tensile) Modulus | 210 GPa |

Standard Specifications of Corresponding Countries

•ASTM: ASTM A240, ASTM A269, ASTM A312, ASTM A469.

•EN: EN 1.4652, EN 10088-3.

Popular Grades

•654SMO: It is a common grade with extremely high corrosion resistance, which is equivalent to UNS S32654 and is widely used in various fields requiring high corrosion resistance.

•X1CrNiMoCuN24-22-8: It is a grade in the EN standard and has similar chemical composition and performance to UNS S32654.

Popular Questions and Answers

Q: What are the main application fields of UNS S32654?

A: It is mainly used in pressurized and erosive systems handling chlorinated seawater at higher temperatures, plate heat exchangers, flue gas cleaning applications, the chemical industry, the pulp and paper industry, desalination, hydrometallurgy, food and beverage, and pharmaceuticals.

Q: Does UNS S32654 have good weldability?

A: Yes, it has good weldability and excellent formability.

Q: How to heat treat UNS S32654?

A: It is not hardenable by heat treatment. Cold working increases tensile strength and hardness. The annealing range is between 1850 and 2050 °F, and it needs to be cooled rapidly.

Products

Phone