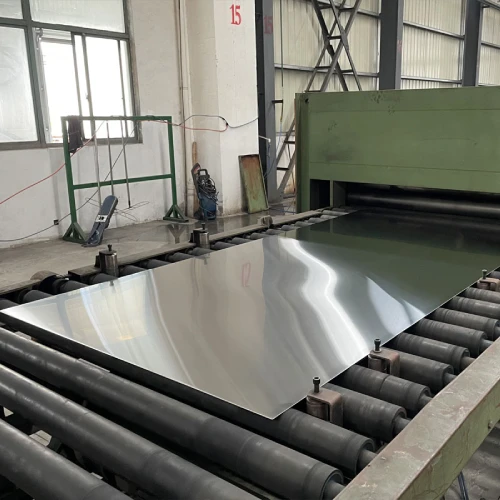

Stainless Steel Sheet

Keywords:

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quote

Keywords:

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quotestainless steel sheets are thin, flat pieces of stainless steel with wide applications, manufactured by hot or cold rolling. They mainly consist of iron and at least 10.5% chromium, which forms a protective oxide layer on the surface, making them resistant to rust, staining, and corrosion.

The following table shows the chemical composition and mechanical properties of some common grades:

| Grade | Chemical Composition (%) | Mechanical Properties | |||||||||

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Tensile Strength (ksi min.) | Yield Strength (min.) | Elongation (min. %) | Hardness Rockwell B (max) | |

| 304 | 0.08 max | 2.00 max | 0.045 max | 0.030 max | 0.75 max | 18.00-20.00 | 8.00-10.50 | 75 | 30 | 40 | 92 |

| 304L | 0.03 max | 2.00 max | 0.045 max | 0.030 max | 0.75 max | 18.00-20.00 | 8.00-12.00 | 70 | 25 | 40 | 92 |

| 430 | 0.12 max | 1.00 max | 0.040 max | 0.030 max | 1.00 max | 16.00-18.00 | - | 65 | 30 | 22 | 89 |

Some standard specifications of stainless steel sheets in different countries are as follows:

| Country | Standard Specification |

| USA | ASTM A167, ASTM A176, ASTM A240M, ASTM A263, ASTM A264, ASTM A265, ASTM A666, A480/A480M |

| Europe | EN 10088-2 |

The more popular grades are 304 and 316. 304 stainless steel is widely used in various fields such as kitchen appliances, food processing equipment, and architectural decoration due to its excellent corrosion resistance and good formability. 316 stainless steel has better corrosion resistance than 304, especially in harsh environments containing chloride ions, so it is often used in marine engineering, chemical equipment, and medical devices.

Popular questions and answers:

Question 1: How to choose the appropriate grade of stainless steel sheet for different applications?

Answer: For general indoor applications with low corrosion requirements, such as kitchen countertops, 304 stainless steel is usually sufficient. For applications in harsh environments such as seawater, chemical plants, or medical equipment that requires high corrosion resistance, 316 stainless steel is a better choice. If magnetic properties are required, 430 stainless steel can be considered.

Question 2: What is the difference between hot rolled and cold rolled stainless steel sheets?

Answer: Hot rolled stainless steel sheets have a rougher surface finish and larger thickness tolerances, but they are generally cheaper and have better formability for some complex shapes. Cold rolled stainless steel sheets have a smoother surface, higher dimensional accuracy, and better mechanical properties, but they are more expensive and may have some residual stress.

Question 3: How to maintain stainless steel sheets to keep their good appearance and performance?

Answer: Regular cleaning with mild detergent and water is recommended to remove dirt and stains. Avoid using abrasive cleaners or tools that may scratch the surface. In addition, for outdoor applications, it is advisable to perform periodic inspections and maintenance to prevent corrosion caused by long-term exposure to the environment.

Products

Phone