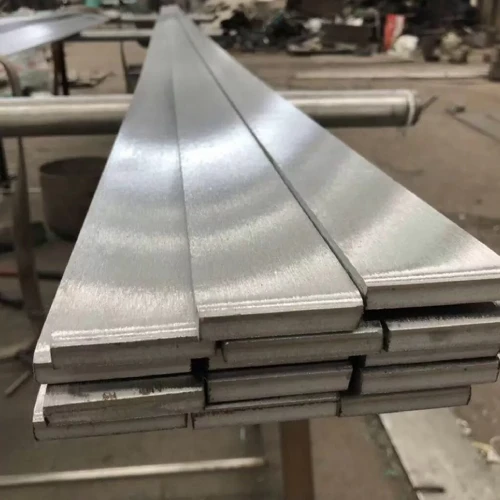

Stainless Steel Flat Bar

Keywords: Flat Bar,

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quote

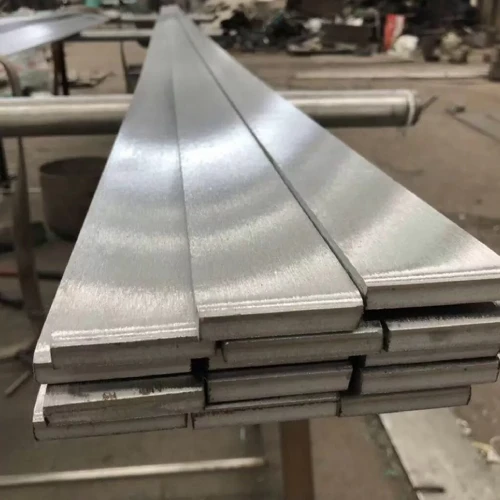

Keywords: Flat Bar,

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A QuoteChemical Composition

stainless steel flat bars typically contain elements such as iron (Fe), chromium (Cr), nickel (Ni), and molybdenum (Mo). The chromium content is crucial as it provides corrosion resistance. For example, in common grades like 304 stainless steel, it contains around 18% - 20% chromium and 8% - 10.5% nickel. Grade 316 has approximately 16% - 18% chromium, 10% - 14% nickel, and 2% - 3% molybdenum, which offers enhanced corrosion resistance, especially in marine and chemical environments.

Mechanical Properties

• Tensile strength: Varies depending on the grade. For 304 stainless steel, it usually ranges from 515 MPa to 760 MPa. 316 stainless steel has a tensile strength in the range of 485 MPa to 620 MPa.

• Yield strength: In 304, it can be around 205 MPa - 310 MPa, while 316 typically has a yield strength of about 170 MPa - 260 MPa.

• Elongation: 304 stainless steel shows good elongation, often around 40% - 60%, allowing for some formability. 316 has elongation values in the range of 35% - 50%.

Standard Specifications of Corresponding Countries (Table)

| Country | Standard Specification |

| USA | ASTM A276, ASTM A484 |

| China | GB/T 1220, GB/T 4226 |

| Germany | DIN 17440, DIN 17441 |

Popular Grades

Grade 304: Widely used in various industries due to its good balance of corrosion resistance, formability, and cost-effectiveness. It is suitable for kitchen appliances, food processing equipment, and architectural applications.

Grade 316: With its superior corrosion resistance, especially against chlorides, it is favored in marine, pharmaceutical, and chemical processing industries. It is used for making components that come into contact with seawater, chemicals, and corrosive substances.

Popular Questions and Answers

Question: What is the main difference between 304 and 316 stainless steel flat bars?

Answer: The main difference lies in the chemical composition. 316 contains molybdenum which gives it enhanced corrosion resistance compared to 304, especially in chloride-rich environments. So, 316 is more suitable for harsh corrosive conditions.

Question: Can stainless steel flat bars be welded easily?

Answer: Most stainless steel flat bars, like 304 and 316, can be welded. However, proper welding procedures and filler materials need to be selected to maintain the corrosion resistance and mechanical properties. For example, using argon gas shielding during welding helps prevent oxidation.

Question: How do I choose the right grade of stainless steel flat bar for my outdoor project?

Answer: If your outdoor project is in a relatively mild environment without significant exposure to saltwater or harsh chemicals, grade 304 might be sufficient. But if it's near the ocean or in an area with high humidity and potential chemical exposure, grade 316 would be a better choice as it can withstand the corrosive elements better.

Products

Phone