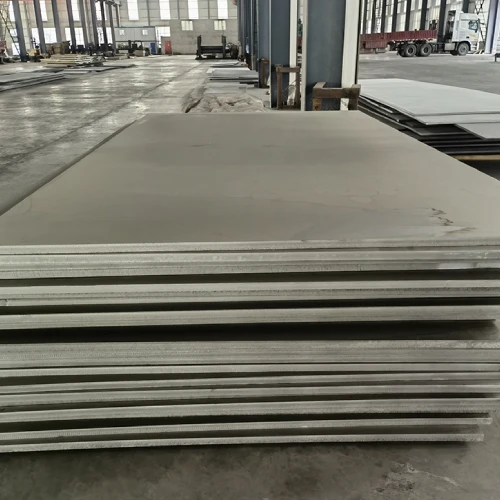

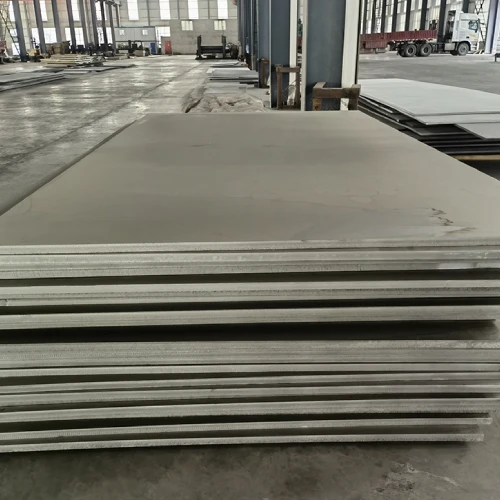

Stainless Steel Plates

Keywords:

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quote

Keywords:

Standard: ASTM, AISI, DIN, EN, GB, JIS

Technique: Hot Rolled/Cold Rolled/Galvnized

Processing Service: Welding, Punching, Cutting

Available Size Range: Click here

Volume: 0

Get A Quotestainless steel plates are widely used in various industries due to their excellent corrosion resistance and durability.

Chemical Composition:

Typically, stainless steel contains iron (Fe) as the main element, along with chromium (Cr), nickel (Ni), molybdenum (Mo), and other alloying elements. For example, in common 304 stainless steel, chromium content is around 18 - 20%, nickel about 8 - 10.5%. The chromium forms a passive oxide layer on the surface, providing corrosion resistance.

Mechanical Properties:

It generally has good tensile strength, yield strength, and elongation. For instance, 304 stainless steel has a tensile strength of around 515 - 760 MPa, yield strength of 205 - 310 MPa, and elongation at break of about 40 - 60%. These properties make it suitable for different forming and machining processes.

Standard Specifications of Corresponding Countries in a Table:

| Country | Standard Specification |

| USA | ASTM A240 (covers various grades and thicknesses for stainless steel plates used in different applications) |

| Germany | DIN EN 10088 (defines material properties, dimensions, and tolerances) |

| China | GB/T 3280 (specifies requirements for stainless steel cold-rolled plates and sheets) |

Popular Grades:

• Grade 304: It is the most commonly used grade, suitable for a wide range of applications like kitchenware, architecture, and food processing due to its good corrosion resistance and formability.

• Grade 316: With the addition of molybdenum, it has enhanced corrosion resistance, especially in chloride-rich environments. Commonly used in marine and chemical industries.

Popular Questions and Answers:

Q1: How can I distinguish between genuine 304 and fake 304 stainless steel?

A: One way is through a chemical analysis test to check the chromium and nickel content accurately. Also, magnetic properties can give a hint. Genuine 304 is usually weakly magnetic, while if it shows strong magnetism, it may be an inferior or mislabeled product.

Q2: What is the best way to clean stainless steel plates?

A: Use a mild detergent and warm water, and wipe with a soft cloth. Avoid using abrasive cleaners or steel wool as they can scratch the surface and damage the passive oxide layer, reducing corrosion resistance.

Q3: Can stainless steel plates be welded?

A: Yes, most stainless steel grades can be welded. However, proper welding procedures and filler materials need to be selected according to the grade to ensure good weld quality and maintain the corrosion resistance of the joint area.

Products

Phone